End-to-end with IoT

To map end-to-end processes that go beyond SAP ERP, we offer our own products as well as individual, IoT-based solutions, which we build from standardized, tried-and-tested modules and components wherever possible. As a result, even individual solutions lose much of their project character, become more cost-effective and are implemented more quickly - in line with the needs of SMEs. As our solutions are SAP-related or integrated, we avoid unnecessary interfaces and third-party systems.

END-TO-END PROCESSES

End-to-end processes place the customer at the center of the company's activities: starting from a customer need, "something" flows into company systems and then back to the customer at the end. All activities that support and flank this process should be coordinated as seamlessly as possible - even across system boundaries - so that the customer's needs are met as quickly as possible. The more efficiently these processes run, the more profitably a company can meet customer needs. With this in mind, the smaller the number of systems a process runs through, the easier it is to handle and the easier it is to incorporate automation.

On the one hand, process automation is based on linking sub-processes, on the other hand it requires (real-time) data-supported intelligence: logics stored in the system and machine-learned empirical values provide the basis for autonomous decisions and the initiation of subsequent processes. Ideally, the employee only has to intervene in exceptional cases or unexpected events (exception-based action). This enables the cost-efficient realization of individual customer requirements through to batch size 1 production orders.

All of this can be mapped within modern, intelligent ERP systems such as SAP S/4HANA. However, a complete end-to-end process goes beyond the boundaries of ERP: areas in production, logistics or products in customer use (whose constant availability is part of the customer requirement) are often outside the system - IoT technology can help to close this gap.

END-TO-END TO THE "THING"

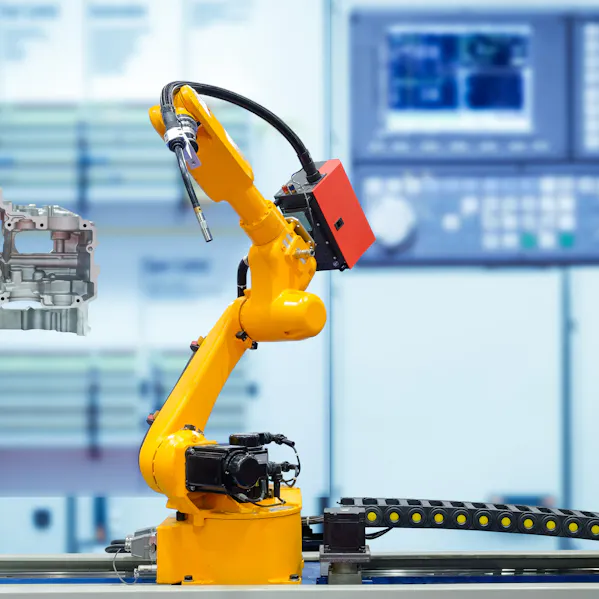

Real-time data from machines and sensors, as well as information on manual work progress recorded via AutoID or feedback terminals, can be combined with process data and used for the intelligent automation of processes:

- For example, machines can deliver status data to a cloud environment (Big Data), where it can be analyzed and examined for patterns or correlations with malfunctions and failures. The (summarized) findings - such as forecasts of impending failures - can proactively trigger the deployment of service technicians or spare parts orders.

- Another example is the continuous recording of order progress in in-house production. These can be integrated into the ERP in real time so that detailed planning, for example, can be continuously optimized and the plant manager can implement optimal utilization of all available resources.

In (I)IoT scenarios, it is generally advisable to differentiate between concepts for in-house production (internal perspective - "IIoT") and for products used by customers (external perspective - "IoT"), as different processes and business areas are affected in each case.

As a digitalization partner for SMEs, our core interest lies in transforming such sometimes technologically demanding scenarios into solutions that are as easy to implement and operate as possible and reducing complexity wherever possible. With this in mind, we work close to or integrated with SAP and try to avoid complex third-party systems, such as an MES, with additional interfaces. Our solutions are geared towards clearly tangible use cases and, wherever possible, we build them on a modular basis using tried-and-tested components. In this way, we ensure that our customers achieve their goals with investments that are appropriate for SMEs and benefit from simple scalability.

You want to know more or to get in touch with us?